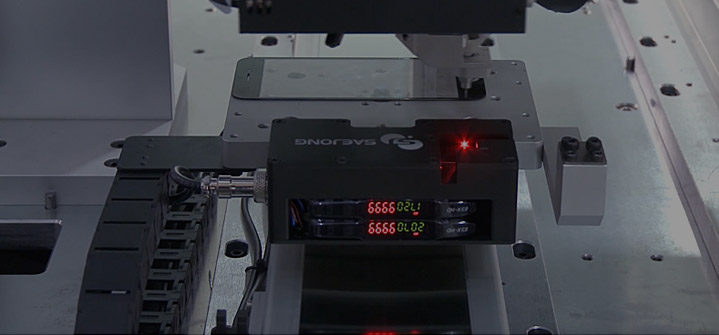

High precision requirementsresponse

The mobile phone screen dispensing process requires extremely high precision, and the amount of glue applied must be uniform and precise.There are many types of glue

Commonly used types of glue for mobile phone screens include UV light-curing adhesives, heat-curing adhesives, conductive adhesives, AB hybrid structural adhesives, etc., each with different characteristics.Production efficiency and quality balance

The use of automated dispensing equipment greatly improves production efficiency, reduces human operation errors, and improves overall production stability and quality control capabilities.Environmental control requirements

The dispensing process has high requirements for the production environment, and factors such as temperature, humidity, and cleanliness will affect the bonding effect of glue.Durability and stability

The choice of glue should be able to withstand daily friction, thermal expansion and contraction, and aging problems in long-term use.

Quickly contact us

Driven by innovation, with excellent products and services